As a new type of grinding equipment with significantly improved performance, the vertical mill integrates drying, grinding, grading, and conveying. It has high grinding efficiency, low power consumption, large feed particle size, easy adjustment of product fineness, simple equipment process flow, small footprint, low noise, low dust, easy use and maintenance, low operating costs, and low consumption of wear-resistant materials. It has demonstrated advantages such as high yield, stable operation, environmental protection, and low-carbon in various application fields, becoming an important tool to improve the efficiency of graphite electrochemical processing and ensure the effective use of graphite electrochemical technology. Currently, the fields of graphite electricity and carbon are developing rapidly, and the applications of graphite electricity are gradually being reflected in various fields, resulting in a significant increase in market value. Carbon vertical mill has become an important equipment for the production of graphite electric materials.

Graphite electric * * material refers to a high-temperature resistant graphite conductive material made from petroleum coke and asphalt coke as aggregates, coal tar as binder, through raw material calcination, crushing and grinding, batching, kneading, forming, roasting, impregnation, graphitization and mechanical processing. Graphite electric * * material can be divided into three types according to quality: ordinary, high, and * * power. The production requirements of graphite electric * * material for different purposes will also vary. At this time, it is necessary to equip a carbon vertical mill that can meet the diversified powder production needs.

The main raw material for the production of graphite electricity is petroleum coke. A small amount of asphalt coke can be added to ordinary power graphite electricity, and the sulfur content of both petroleum coke and asphalt coke cannot exceed 0.5%. Needle coke is also required when producing high-power or * * power graphite electricity * *. The main raw material for aluminum production is petroleum coke, and the sulfur content is controlled to be no more than 1.5% to 2%. Petroleum coke and asphalt coke should comply with relevant national quality standards.

Graphite electric * * material is an artificial high-temperature resistant graphite conductive material. The main production process is to use petroleum coke and asphalt coke as aggregates, coal tar as binders, and go through calcination, crushing and grinding, batching, forming, calcination, graphitization and other processes. Graphite electric materials can be divided into three types based on their quality: ordinary, high, and high power. The production requirements for graphite electric materials for different purposes will also vary. At this time, it is necessary to equip a carbon vertical mill that can meet diverse powder production needs.

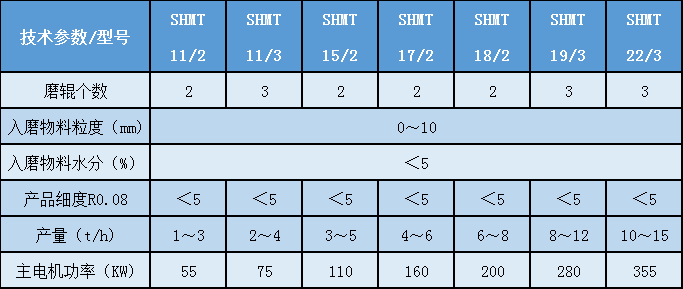

Technical parameters