【Product Overview】

Vertical coal mill, also known as coal mill or coal vertical mill, is an energy-saving coal powder production equipment suitable for grinding medium hardness materials such as raw coal and bituminous coal. It can be widely used in powder production systems in industries such as power, metallurgy, building materials, and chemical engineering, especially in a large number of coal injection powder production systems used for burning smokeless coal.

Against the backdrop of the country's strong promotion of coal utilization, the coal powder preparation industry will receive strong support from national policies, and the adoption of vertical coal mills by coal powder preparation enterprises will undoubtedly achieve huge economic and social benefits.

【 Application Fields 】

Industries such as building materials, chemicals, metallurgy, electricity, and coal powder preparation.

【Applicable Materials】

Bituminous coal, smokeless coal, lignite, etc.

【Performance Characteristics】

1. High grinding efficiency and low grinding energy consumption. Compared with traditional wind swept ball milling with the same scale of production, the power consumption of grinding is reduced by 20-40%, especially in cases where the moisture content of raw coal is high, the energy-saving effect is even greater.

2. High drying capacity. The vertical coal mill adopts an air sweep operation, which can grind raw coal with a moisture content of up to 15-20% by adjusting the inlet air temperature and air volume. The use of air swept ball mills has limited drying capacity, while the use of vertical coal mills can solve its high moisture requirements with high air volume.

3. The grinding particle size is large, up to 5% of the diameter of the grinding roller, so large and medium-sized grinding can eliminate secondary crushing.

4. The fineness of the product can be easily controlled by adjusting the rotor speed of the dynamic and static separator, and the fineness of coal powder can reach R0.08 ≤ 2%. And the fineness is stable and the particle size is uniform, which is conducive to coal powder combustion and very suitable for grinding inferior coal and anthracite.

5. The process flow is simple, the footprint is small, the building area is small, and it can be arranged outdoors. The vertical mill integrates five processes: crushing, grinding, drying, powder selection, and conveying. The process is simple, the layout is compact, and the footprint is about 60-70% of the ball milling system. The building area is about 50-60% of the ball milling system.

6. Low noise, minimal dust, and clean operating environment. The vertical grinding noise is only 80-85dB, which is 20-25dB lower than ball milling. The system works under negative pressure without dust flying, and the operating environment is clean.

7. The grinding material consumes less and has a long lifespan. High operating rate. Due to the installation of a limit device in the vertical mill, there is no direct contact between the roller sleeve and the lining plate, resulting in low vibration amplitude of the mill, long service life of the grinding body, and high operating rate.

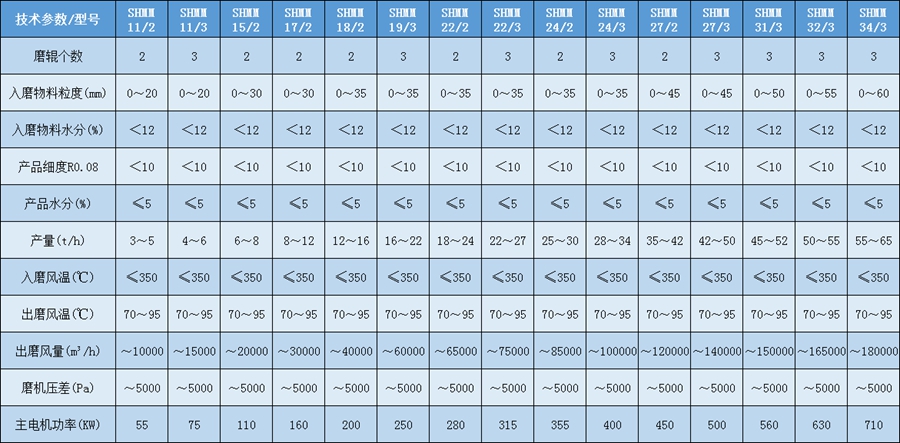

【Technical Parameters】