【Equipment Overview】:

The SHCX Shenhai Fine Grinding Machine is a new type of grinding equipment manufactured by our factory based on years of experience in grinding machine production. The powder mill, which integrates grinding, grading, and conveying, has become one of the * * equipment in the powder industry.

【 Application Fields 】:

Widely used in industries such as chemical, metallurgical, non-metallic minerals, etc.

【Applicable materials】:

Non metallic ores such as limestone, calcite, talc, barite, and dolomite, non flammable and non explosive ores, non corrosive brittle materials in granular and powdered form.

【Working principle】:

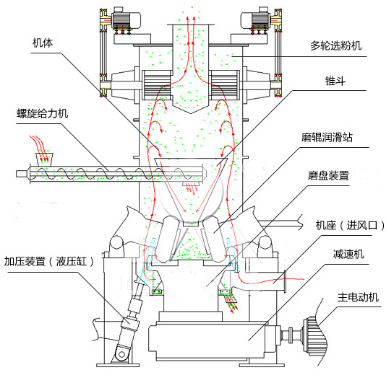

The material falls onto the grinding disc through the spiral feeder, and the centrifugal force generated by the rotation of the grinding disc driven by the reducer of the main motor drives the material to move uniformly around the grinding disc. When the material passes through the roller area on the grinding disc, it is crushed by the grinding rollers, and large pieces of material are directly crushed, while smaller particles are compressed to form a material bed for inter particle crushing. After being crushed, the material continues to move towards the edge of the grinding disc and is brought into the powder selection machine for classification by the airflow entering from the air inlet. Under the action of the powder selection machine blades, the powder that does not meet the particle size requirements falls into the grinding disc for re grinding. The powder that meets the standard enters the pulse dust collector with the airflow through the powder selection machine for collection, and the collected and discharged powder is the finished powder. Impurities such as iron blocks mixed in the material, due to their difficulty in grinding and high gravity, cannot be carried away by the airflow when passing through the edge of the grinding disc and fall into the lower chamber of the mill. They are then sent to the slag discharge port by the scraper plate and discharged outside the main machine.

【Product Advantages】:

1. Excellent quality of finished products

Adopting the principle of vertical abrasive layer grinding, the material stays in the mill for a short time, reducing repeated grinding, resulting in a low iron content and high whiteness and purity of the product. The powder content of finished products with particle size less than 2 μ m can reach 70%, achieving low residue of 325 mesh, and can increase secondary powder selection to select finer particle size finished products.

2. High grinding efficiency

The host speed adopts variable frequency speed regulation, which is widely applicable to various materials. The specially designed roller sleeve and liner grinding curve are easier to form a material layer than ordinary vertical mills, and can grind to the desired product fineness in one go. The use of mechanical and electronic dual limit protection devices effectively prevents direct contact between the roller sleeve and the grinding disc liner, avoiding destructive impacts and severe vibrations.

3. High level of environmental protection

Low vibration and noise. The equipment is sealed as a whole and operates under negative pressure, with no dust spillage and a clean environment. The environmental protection requirements are higher than national standards.

4. Good economic benefits

The principle of multi head powder selection machine, and each rotor adopts variable frequency speed regulation, can achieve the fineness of the ground product within the selected range, without the need for secondary sorting and the presence of waste materials.

5. Low cost investment

Equipped with an automatic control system, it can achieve remote control and is easy to operate. The grinding roller pressure control method adopts PLC/DCS automatic control, and the grinding pressure is controlled without manual operation. The grinding roller and grinding disc in work do not come into contact, and the grinding roller and lining plate are made of * * material, which has less wear and a long service life. The grinding roller can be flipped out of the machine casing for maintenance, making it convenient and quick to replace the roller sleeve and lining plate, reducing downtime losses. The grinding roller lubrication adopts a separate lubrication station, and the single grinding roller circuit adopts a dual pump pump suction simultaneous operation mode, which not only provides sufficient lubrication and cooling for the grinding roller bearings, but also avoids excessive oil accumulation and leakage in the grinding roller bearing chamber.

【Technical Parameters】

技术参数/型号 | SHCX | SHCX | SHCX |

磨盘中径(mm) | 1100 | 1300 | 1500 |

磨辊个数 | 3 | 3 | 3 |

入磨物料粒度(mm) | 0~10 | 0~10 | 0~10 |

入磨物料水分(%) | <3 | <3 | <3 |

产品细度(目) | 325~1250 | 325~1250 | 325~1250 |

产量(t/h) | 5~14 | 7~16 | 9~18 |

主电机功率(KW) | 250 | 315 | 355 |

分级机功率(KW) | 75 | 105 | 154 |