【Equipment Overview】:

As a new type of admixture for high-performance concrete, slag powder has the advantages of improving various properties such as compressive strength, tensile strength, shear strength, and bending strength of concrete. At present, replacing the amount of cement in concrete and cement products with slag powder has become the mainstream trend in the building materials industry. SHMK slag vertical mill is a specialized equipment for grinding industrial waste into powder. It integrates crushing, conveying, grinding, and drying, and is an ideal equipment for producing slag powder.

【 Application Fields 】:

Widely used in industries such as cement, commercial concrete, and grinding stations.

【Applicable materials】:

Slag, steel slag, water slag, manganese slag, etc.

The slag vertical mill is driven by an electric motor to drive a reducer, which in turn drives the grinding disc to rotate. The material falls onto the grinding disc from the feed inlet through a locked air feeder, while hot air enters the mill from the inlet. As the grinding disc rotates, the material moves towards the edge of the grinding disc under the action of centrifugal force. When passing through the annular groove on the grinding disc, it is crushed by the grinding roller. The crushed material is carried up by the high-speed airflow of the wind ring at the edge of the grinding disc, and the large particles directly fall onto the grinding disc for re grinding. When the material in the airflow passes through the upper separator, the coarse powder falls from the cone hopper to the grinding disc for re grinding under the action of the rotating rotor. The qualified fine powder is ground together with the airflow and collected by the dust collection device, which is the product. The material containing moisture is dried in contact with the hot air flow. By adjusting the temperature of the hot air, it can meet the requirements of different humidity materials and achieve the required product moisture. By adjusting the separator, the desired thickness for different products can be achieved.

【Performance Characteristics】

1. The slag vertical mill integrates crushing, drying, grinding, and graded conveying, with a simple system and compact layout. It occupies about 50% of the same ball milling system and can be arranged outdoors, thus significantly reducing investment costs.

2. The slag vertical mill uses grinding rollers to directly crush and grind materials on the grinding disc, which has low energy consumption and saves 30% to 40% energy consumption compared to the same ball milling system.

3. Due to the fact that the grinding roller of the slag vertical mill does not directly contact the grinding disc during work, and the grinding roller and lining plate are made of * * material, the service life is long and the wear is minimal.

4. The slag vertical mill is equipped with an automatic control system, which can achieve remote control, easy operation, and a device to prevent direct contact between the roller sleeve and the grinding disc liner, avoiding destructive impact and severe vibration.

5. Due to the short residence time of materials in the slag vertical mill, it is easy to detect and control the particle size and chemical composition of the product, reduce repeated grinding, and stabilize product quality.

6. The hydraulic opening system of the slag vertical mill can replace roller sleeves, liners, etc. by flipping the boom, which is convenient and fast, reducing downtime losses. In addition, the slag vertical mill has low vibration and noise, and the equipment is sealed as a whole. The system works under negative pressure without dust overflow, and the environment is clean, meeting national environmental protection requirements.

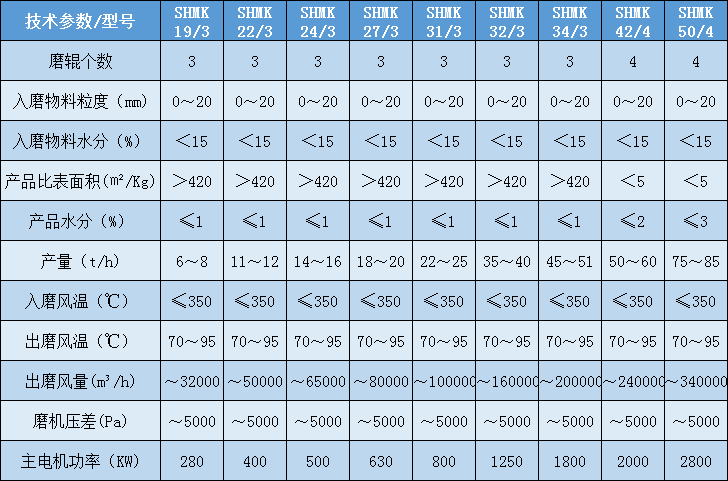

【Equipment Parameters】

Note: Bond index of slag grindability ≤ 25kWh/t; Steel slag grindability (Bond) index ≤ 30kWh/t; When grinding steel slag micro powder, the output decreases by about 30-40%.